INDUSTRY INSIGHT | HEALTHCARE

Hospital Equipment Tracking: How Wheelchair Tracking Saves Nurses 60 Minutes Per Shift

Introduction

Today, the medical field is in crisis. Despite the shortage of doctors and nurses, patient numbers are increasing every day. A never-ending waiting list that sometimes takes over 10 hours. As a result, people cannot get the sufficient medical treatment they need on time, which sometimes leads to fatal incidents. At the hospital, busy and crowded as always, improving efficiency between procedures is crucial, but there are obviously manual bottlenecks to resolve.

Here is one scenario: Sarah, a nurse, has just received the green light to discharge a patient. The patient is dressed, her prescriptions are ready, and her son is waiting in the parking lot. Everything is ready except the wheelchair. Sarah was struggling with finding a wheelchair. She checked the discharge bay, but nothing was found. The storage closet was empty. She walks to the other end of the unit, peers into patient rooms, and finally asks a colleague who thinks there might be one near the elevators. Twelve minutes later, Sarah finally returned to the patient with a wheelchair. The discharge was delayed, her son waited for a while and got frustrated, and Sarah lost precious time she could have spent with other patients who needed her.

This scenario plays out in hospitals across the country, every single day. A report by Vizzia Technologies and Georgia State University (2024) says that nurses spend up to 60 minutes per shift searching for lost equipment. Nurses are losing time that could be spent on direct patient care, medication administration, or critical assessments for something that we can resolve every single day.

But the real cost goes far beyond wasted minutes. It touches everything from staff morale to patient satisfaction to your hospital's bottom line.

The Hidden Cost of "Just Finding a Wheelchair"

When we talk about equipment tracking, it's easy to focus solely on the hard costs such as replacement expenses, capital budgets, and depreciation schedules. But the operational impact of missing wheelchairs creates a ripple effect that operations managers see every day in their workflows.

The Productivity Drain

According to research cited by Healthcare Dive, nurses spend roughly one week per month hunting for equipment and supplies. Wheelchairs are among the most frequently misplaced items, requiring staff to search across multiple floors and departments, through storage areas, patient rooms and common spaces, and multiple times per shift for discharges, tests, and procedures.

This isn't just an inconvenience, but it's a fundamental operational inefficiency that compounds across your facility.

The Patient Experience Impact

While staff search for wheelchairs, patients wait, which leads to measurable consequences:

Delayed discharges: Patients ready to go home sit in their rooms longer, backing up the entire discharge process and creating bottlenecks for incoming admissions.

Extended wait times: Patients scheduled for tests or procedures experience delays that cascade throughout the day's schedule.

Compromised care quality: When nurses spend time hunting for equipment, they have less time for the assessments, education, and bedside care that directly impact patient outcomes.

These delays can affect your hospital's satisfaction scores and reputation, as well as reimbursement rates. According to a Relias article, in the US, patient satisfaction scores account for 25-30% of Medicare reimbursement through the Hospital Value-Based Purchasing program. And it is publicly visible on the CMS Hospital Compare website to prospective patients choosing where to receive care.

The Staff Morale Problem

Healthcare workers are already operating under immense pressure. Staffing shortages, increased patient acuity, and administrative burdens contribute to alarming rates of burnout and turnover. Adding the frustration of searching for basic equipment like wheelchairs that should simply be there when needed compounds these challenges.

When staff can't trust that equipment will be available, they develop workarounds. Some start hoarding wheelchairs in their units or hiding them in supply closets "just in case." This behaviour makes the problem worse by removing equipment from circulation and creating artificial shortages.

The result is a cycle of distrust, inefficiency, and frustration that erodes the work environment for everyone.

Why Wheelchairs Disappear: The Hidden Attrition Problem

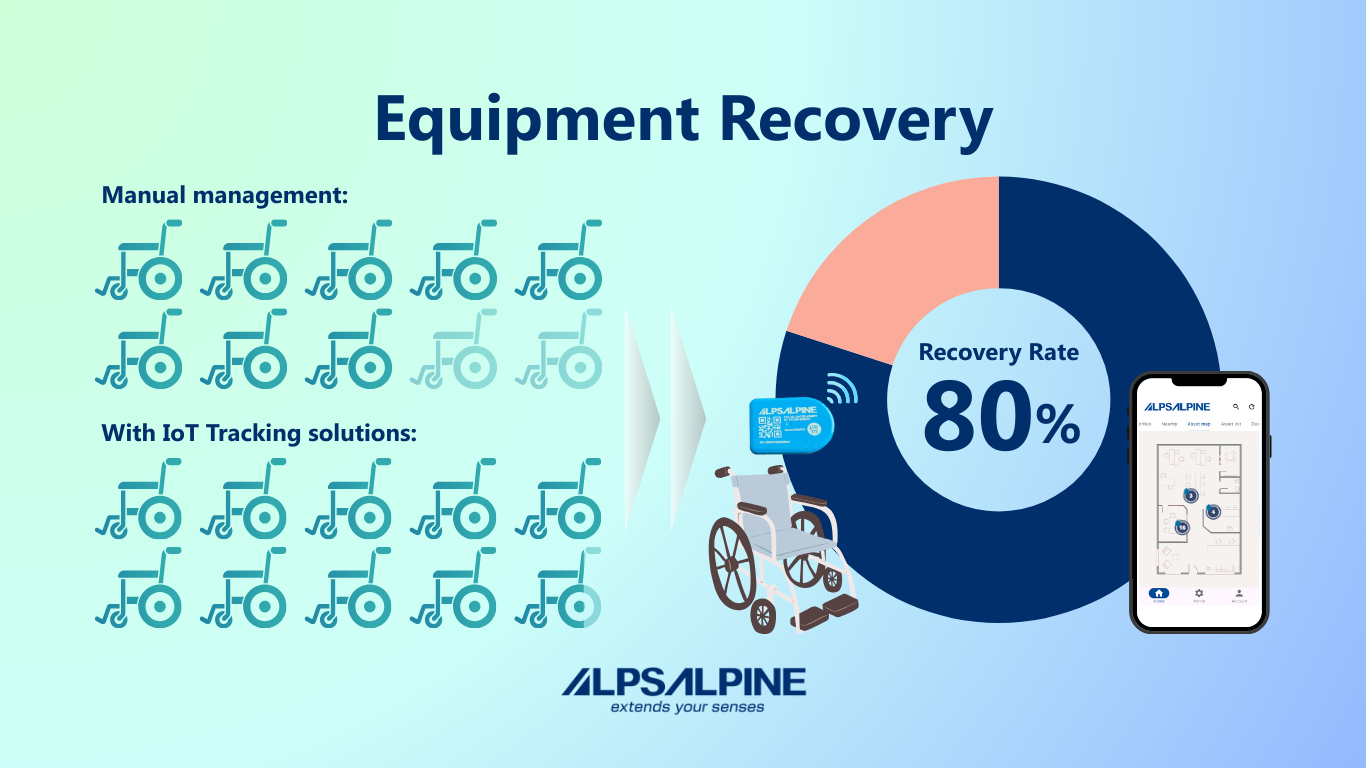

Research shows that between 10% and 20% of a hospital's mobile assets, including wheelchairs, are lost or stolen while they are still usable. Let’s do some quick math. For a facility with 100 wheelchairs, that means losing 10 to 20 units annually that must be replaced.

At an average replacement cost of $500-700 per wheelchair, even a 10% loss rate means $5,000-7,000 in annual replacement costs for every 100 wheelchairs in your fleet. But understanding where these wheelchairs go helps illuminate why traditional inventory management approaches aren't working.

The Accidental Take-Home

The most common form of wheelchair loss isn't malicious. It's simply patients taking them home after discharge. During the chaos of leaving the hospital, especially if a family member is handling logistics, a wheelchair used for transport to the car can easily end up in a trunk and be driven away.

Sometimes patients genuinely believe the wheelchair is part of their discharge equipment. Other times, in the rush to get home, no one realizes the wheelchair needs to be returned. By the time the hospital identifies the loss (if it ever does), the wheelchair is miles away.

The Disposal Room Dilemma

Hospital equipment has an unfortunate tendency to end up where it shouldn't be. Wheelchairs get left in patient rooms after transport, and during room turnover, they're sometimes accidentally included with trash bags or soiled linen being hauled away.

Once equipment reaches the main trash or laundry collection areas, recovery becomes nearly impossible. The window for retrieval is measured in minutes, not hours, and without a tracking system to alert staff immediately, valuable equipment is simply disposed of.

Intentional Theft and Resale

While less common than accidental loss, intentional theft is a real problem. Medical equipment, including wheelchairs, has resale value. There are documented cases of hospital equipment appearing on online marketplaces like eBay and Craigslist after disappearing from facilities.

Hospitals are inherently open environments with multiple access points and high foot traffic. Unlike retail stores, they can't lock down exits or implement aggressive security measures without impacting patient care and emergency access. This accessibility, while necessary, creates vulnerability.

The Lost-on-Campus Problem

In large hospital systems or multi-building campuses, wheelchairs tend to migrate. A wheelchair used to transport a patient to radiology stays there. One used for a cafeteria visit gets left by the entrance. Over time, wheelchairs accumulate in unexpected locations, such as storage rooms and mechanical areas, or are simply abandoned in hallways far from where they're needed.

These wheelchairs aren't technically lost, but they're functionally unavailable. Without visibility into their locations, they might not exist.

The Real Cost Adds Up

Santa Clara Valley Medical Center reported losing more than $11 million in medical equipment over the past 4 years. While not all of this was wheelchairs, the example illustrates how equipment losses scale across a facility.

And that doesn't account for the productivity losses, delayed patient care, or the cost of over-purchasing to compensate for chronic shortages.

How Real-Time Tracking Solves Multiple Problems

Physical asset tracking technology transforms wheelchair management from a reactive scramble into a proactive system. The impact isn't theoretical—hospitals that implement real-time location systems see measurable improvements across multiple operational areas.

Immediate Location Visibility

Instead of Sarah walking floor to floor searching for a wheelchair, she opens a dashboard on her mobile device and sees exactly where the nearest available wheelchair is located. The search that took 12 minutes now takes 30 seconds.

Modern tracking systems using Bluetooth Low Energy (BLE) or RFID technology provide room-level accuracy. Staff can see not only that a wheelchair is on the fourth floor, but also that it's in Room 412 or parked in the discharge bay.

This visibility has cascading benefits:

• Faster patient discharges

• More efficient transport to tests and procedures

• Reduced staff frustration and walking distance

• More nursing time available for direct patient care

Geo-Fencing and Theft Prevention

Geo-fencing technology creates virtual boundaries around your facility. When a tagged wheelchair crosses these boundaries—say, heading toward the parking lot or an unauthorized exit—the system immediately sends an alert to designated staff members.

This addresses both the accidental take-home problem and intentional theft. When a patient is being discharged, and a wheelchair starts moving toward the parking garage, staff receive a real-time notification. They can politely intercept the equipment before it leaves the premises.

The mere presence of a visible tracking system also serves as a deterrent. When staff and visitors know that equipment is actively monitored, the likelihood of opportunistic theft drops significantly.

Preventing Disposal Room Losses

Tracking systems can monitor specific zones within your facility, including trash collection areas and soiled linen rooms. When a wheelchair enters one of these high-risk zones, an immediate alert allows staff to retrieve it before it's hauled away with waste.

This creates a safety net for the inevitable moments when equipment is left in the wrong place amid the chaos of room turnover or patient transport.

Data-Driven Inventory Management

Real-time tracking generates valuable usage data that helps operations managers make smarter decisions about inventory levels and distribution:

Utilization patterns: See which units use the most wheelchairs and when peak demand occurs

Distribution optimization: Identify if certain areas are consistently short while others have excess inventory

Right-sizing inventory: Determine if you actually need more wheelchairs or if you just need better visibility of existing ones

Movement history: Understand typical wheelchair journey patterns to inform better staging locations

Many hospitals discover they don't need to purchase additional wheelchairs—they simply need to make better use of the ones they already own.

Eliminating Hoarding Behaviour

When staff have confidence that they can instantly locate a wheelchair when needed, the incentive to hoard equipment disappears. Units no longer need to hide wheelchairs in supply closets or patient rooms as insurance against shortages.

This behavioural shift alone can significantly improve equipment availability across your facility without adding a single new wheelchair to inventory.

What to Consider When Evaluating Tracking Solutions

Not all asset tracking systems are created equal, and what works for one hospital may not be the right fit for another. As you evaluate solutions for your facility, consider these key factors:

Accuracy Requirements for Your Facility

Different tracking technologies offer varying levels of location precision:

Zone-level tracking: Identifies which floor or general area the equipment is located in

Room-level tracking: Pinpoints equipment to specific rooms or areas (3-5 meter accuracy)

Sub-room tracking: Provides precise location within a room (1-3 foot accuracy)

For wheelchairs, room-level accuracy typically provides the best balance of usefulness and cost. Sub-room precision is usually overkill, while zone-level tracking may not be specific enough to eliminate search time.

Integration with Existing Hospital Systems

The most effective tracking solutions don't operate in isolation. Consider how a system will integrate with:

• Your existing IT infrastructure and network

• Electronic health records (EHR) for patient-equipment associations

• Biomedical equipment maintenance systems

• Facility management and work order systems

Seamless integration reduces duplicate data entry and creates a single source of truth for asset information.

Scalability Across Departments and Campuses

You might start by tracking wheelchairs, but successful implementations often expand to other mobile assets, such as IV pumps, patient monitors, beds, and transport equipment.

Look for systems that can:

• Scale to track thousands of assets across multiple locations

• Support different asset types with varying tracking needs

• Extend across multiple buildings or campus locations

• Grow with your facility's changing needs

Total Cost of Ownership vs. Current Losses

When evaluating solutions, look beyond just the initial hardware and software costs. Consider:

Direct costs: Hardware (tags, sensors), software licenses, installation, training

Ongoing costs: Maintenance, battery replacement, support contracts

Offset savings: Reduced equipment losses, recovered staff productivity, better asset utilization

Intangible benefits: Improved patient satisfaction, reduced staff frustration, faster throughput

Most hospitals find that the productivity recovery alone justifies the investment, with equipment loss prevention as a significant additional benefit.

Implementation Timeline and Staff Training

According to the SAP report, the best technology is useless if staff don't adopt it. Successful implementations require:

• Clear communication about why the system is being implemented

• Simple, intuitive interfaces that don't add complexity to workflows

• Adequate training that meets staff where they are

• Realistic timelines for deployment and adoption

• Ongoing support as the system goes live

The implementation process should enhance staff workflows, not complicate them. Look for solutions that can be deployed incrementally, allowing you to prove value quickly while minimizing disruption.

Recovering Time, Reducing Costs, Improving Care

Twenty minutes a day doesn't sound like much. But multiply it across every nurse in your facility, every single day, and it becomes one of the largest preventable drains on hospital productivity and staff wellbeing.

When wheelchairs are instantly locatable, patients move through your facility more efficiently. Nurses spend their time on care, not searches. Equipment investments are protected, not written off as losses. And perhaps most importantly, your staff regain confidence in their ability to access the tools they need when they need them.

The question isn't whether wheelchair tracking can deliver value—hospitals implementing these systems consistently report measurable improvements across multiple operational metrics. The question is: which specific combination of technology, implementation approach, and operational changes will deliver the best results for your facility?

Every hospital's wheelchair management challenges are unique—from facility layout to patient volume to existing infrastructure. Our team works with you to assess your specific situation and design a tracking solution that delivers measurable ROI for your facility.

Ready to stop the daily equipment hunt?

Contact us to discuss your hospital's needs and discover how much time and money you could recover.

References

1. 24x7 Magazine. (2024). Nurses Searching for Equipment Led to $14B in Lost Productivity. Based on a white paper by Vizzia Technologies and Georgia State University.

2. Healthcare Dive. (2017). Lost and found: Keeping track of healthcare equipment.

3. Chief Healthcare Executive. (2026). Hidden costs of missing medical equipment.

4. Relias. (2024). Higher Reimbursement and Patient Satisfaction Scores.

5. Medical Buyer. (2023). US hospitals lose 10-20% of medical equipment every year.

Contact us!

Got questions? Book a demo and get the answers you need.

Discover how ALPS ALPINE asset trackers can support your operations, with no pressure or obligation to purchase.

Fill out the form below to connect with our team.